-

Knowledge of Antenna Dishes

A parabolic antenna is an antenna that uses a parabolic reflector, a curved surface with the cross sectional shape of a parabola, to direct the radio waves. The most common form is shaped lik...

See More

-

Which monitor arm should I choose?

Once you have determined all of the specifics that will play into your decision, you can select which monitor arm will work the best in your setting:...

See More

-

How will the monitor arm mount attach to my desk?...

If you choose a desk-mounting monitor arm, many models come in either a grommet or c-clamp version.

See More

-

What should I think about when shopping for monitor arms?...

There are many things to consider when shopping for the appropriate monitor arm

See More

-

Why do I need a monitor arm?

There are many ergonomic advantages to using an adjustable monitor mount at your workspace. They allow you to easily place your screen at the appropriate height, depth and angle which will promote g...

See More

-

How-to Basics: Ergonomic Desk Setup

Let‘s get back to the basics of How to set up your desk ergonomically. Desk setup involves everything from your sitting/standing position at your desk to how you effectively arrange the equipment ...

See More

-

What is a Desktop CNC Machine?

Companies that specialize in manufacturing CNC machines often offer a desktop series of smaller, lightweight machines...

See More

-

What is a CNC Machine? Types of CNC Machines and Machine Tools...

Depending on the machining operation being performed, the CNC machining process employs a variety of CNC machines and machine tools to produce the custom-designed part or product....

See More

-

CNC Machining Equipment and Components

As indicated above, there is a wide range of machining operations available. Depending on the machining operation being performed, the CNC machining process employs a variety of software applicat...

See More

-

CNC Lathe Operator Training

To handle a CNC lathe, a machinist should have completed a set amount of coursework and earned appropriate certification from an accredited industrial training organization....

See More

-

How Does a Swiss Machine Work?

Swiss machining, also known as swiss screw machining, uses a specialized type of lathe that allows the workpiece to move back and forth as well as rotate, to enable closer tolerances and better stabi...

See More

-

CNC Machining Tolerances Tables

When specifying parts to a machine shop, it‘s important to include any necessary tolerances. Though CNC machines are very accurate, they still leave some slight variation between duplicates of t...

See More

-

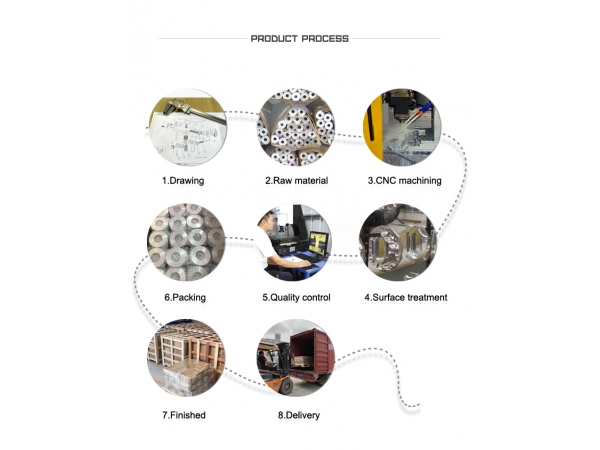

Overview of CNC Machining Process And CAD design...

Evolving from the numerical control (NC) machining process which utilized punched tape cards, CNC machining is a manufacturing process which utilizes computerized controls to operate and mani...

See More

-

What is CNC Machining?

what is CNC Machining?CNC machining is a term commonly used in manufacturing and industrial applications. But exactly what is CNC? And what is a CNC machine?...

See More

-

Coding of CNC Machine

G-codes are used to command specific movements of the machine, such as machine moves or drilling functions. The majority of G-Code programs start with a percent (%) symbol on the first line, then...

See More

-

Positioning control system of CNC Machining...

In numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled by means of either an open-loop or a closed-loop s...

See More

-

Numerical Precision and Equipment Backlash...

Within the numerical systems of CNC programming, it is possible for the code generator to assume that the controlled mechanism is always perfectly accurate, or that precision tolerances are identi...

See More

-

Tool / machine crashing of CNC

n CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, sometimes resulting in bending or breakage of cutting tools, accessory c...

See More

-

History and Machine examples of CNC

Main article: History of numerical control The first NC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follo...

See More

-

CNC Parts Description

Motion is controlling multiple axes, normally at least two (X and Y),and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo ...

See More