|

Material |

Aluminum alloy ADC12, ADC10, A360, A380, A356 |

|

Processing Craft |

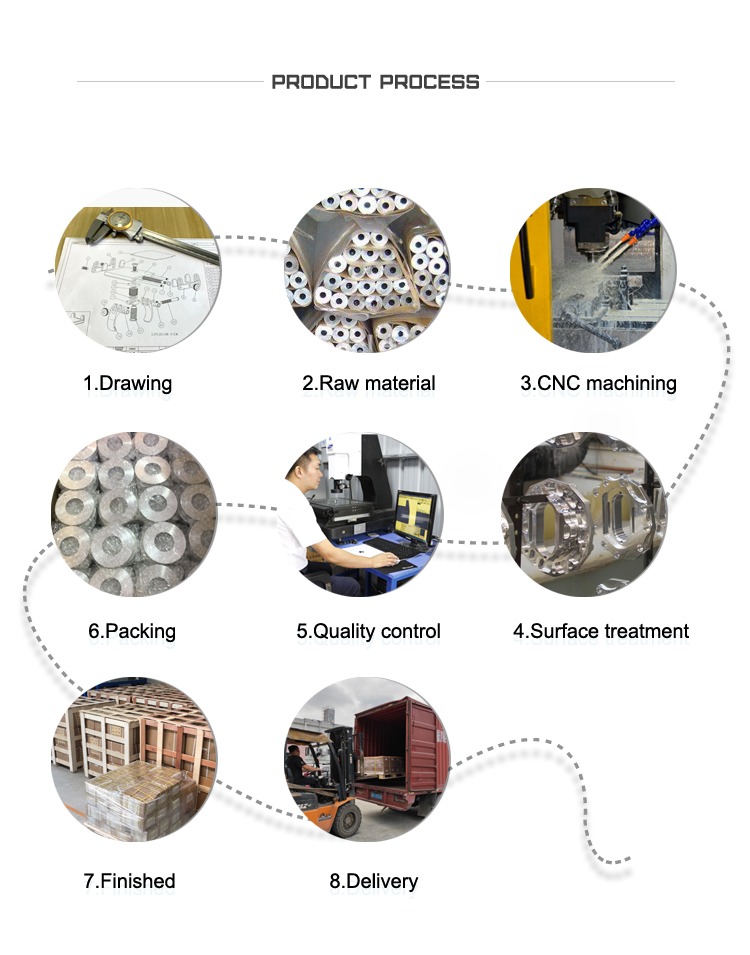

Drawings→ mould making → die casting →rough machining → CNC machining →surface treatment →product checking→ packing →delivery |

|

Tolerance |

± 0.02mm |

|

Surface Treatment |

Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

|

Quality Assurance |

ISO9001:2015 Certified, SGS Certification |

|

Inspection |

1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. 2.Third Party inspection available upon requirement. |

|

Mainly Testing Facility |

Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

|

Quality Guarantee |

Two years |

|

Features & Advantage |

1.High finish appearance, smooth surface roughness is Ra1.6 after machining. 2.The machining precision is high and the assembly structure is seamless. 3.No granules, no spots and no painting peel off in appearance. 4.Smooth appearance, corrosion resistance. 5.Pass Salt Spray Test with 96 Hours. |

|

Standard |

1.Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000, EN1706:1998 |